|

Deformational |

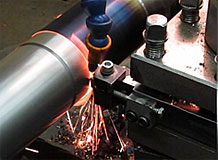

Surface quenching on the lathe without thermal equipment

![]()

The energy released in the area of deformational cutting is used to heat the undercut layer up to the temperatures of structural and phase changes of the material being processed. Heat rate is up to 2 millons degres per second with high degree and rate of deformation.

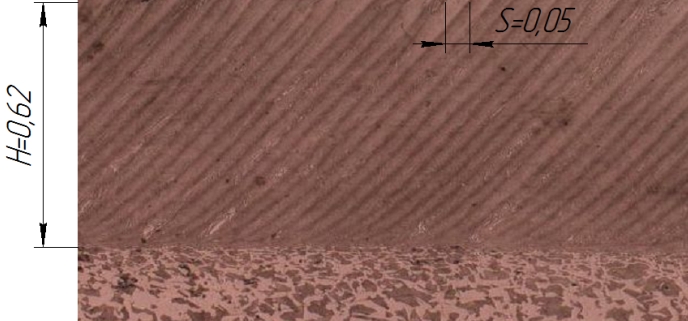

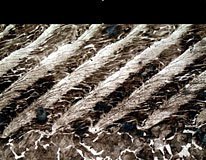

As a result of processing, a unique hardened structure is formed on the surface which consists of inclined, thin undercut layers tightly fitted to each other.

Options are available where the undercut layer is fully hardened in its thickness or only partially hardened.

|

|

|

Fig. 1 - Process of surface guenching |

Fig. 2 - Fully

hardened fins. HRC60. |

Fig. 3 - Partly hardened fins.Hardness HRC54 (hard layers) and HRC32 ("soft" layers). |